Complete product range and scope of applications.

The provisions and characteristics of our Automotive Series applications offer the best market performance:

Automotive Series uses our exclusive ultrasonic plates. These are 25% thicker in comparison with conventional technology, reducing the risk of ultrasonic erosion and breakages due to fatigue, and providing more uniform cleaning. The transducers are built with high-quality phosphorous-copper/silver alloys to minimize the accumulation of heat, to extend the life of the transducers and piezoelectric crystals and to reach the best performance levels. In short, it is the most effective system to automotive engine cleaning with ultrasounds.

Our equipment is completely insulated (including the cover) to avoid heat losses and to ensure quick attainment of the required temperature.

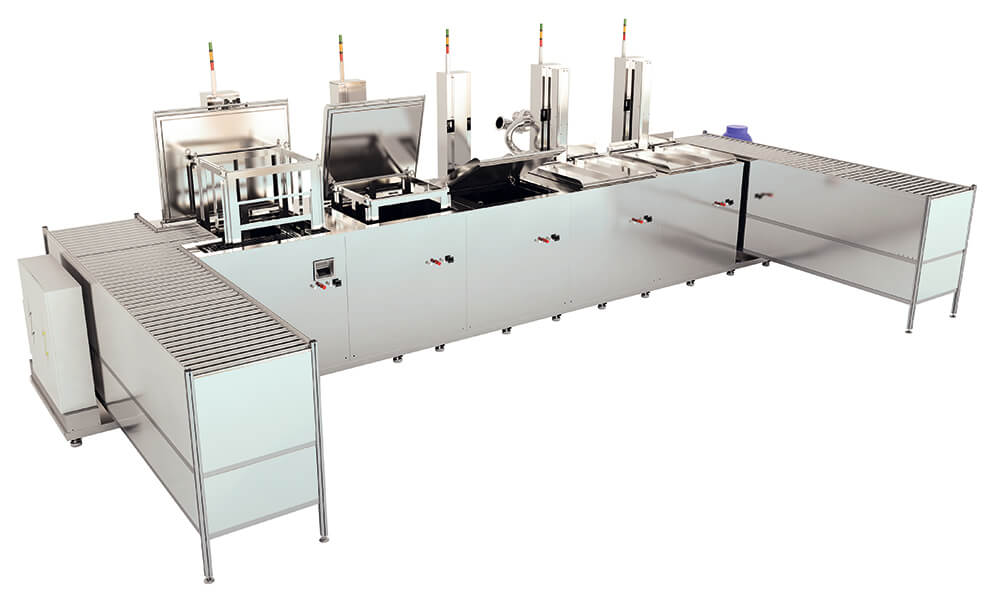

The parts are easily placed in the cleaning tray. The tray is activated pneumatically/hydraulically and can manipulate operation loads up to 2,100 kg or higher.

The parts to be cleaned are shaken inside the deposit during the automotive engine cleaning process so the liquid may agitated inside the tank. This process considerably improves the results.

We have eight different frequent flushings that may be configured to improve performance and to achieve better distribution of the cavitation field with a bandwidth up to 3%.

Our equipment includes a Programmable Automaton (PLC) for process control. The user controls the process through a colour touch-screen in various languages. It can be activated in the automatic mode which does not require the presence of the operator during the automotive engine cleaning process with ultrasound.

After dirt and grease are extracted from the parts, they must be removed from the main barrel. Our exclusive Laminar Flow Separation System (LFSS) takes floating grease to an auxiliary tank where it can be easily removed.

All our machines are completely built in stainless steel. Our thorough quality control systems ensure the non-existence of leaks in weldings or mechanical unions.

This operation mode facilitates the sloughing of specific types of dirt with high adherence levels. Our system cleans automotive engines in a quick, safe and inexpensive manner, and assures that the smallest and most delicate parts are always ready.

UltraTecno relies on the optimal solution for the cleaning of any marine element or energy production plants. train engines and railways components.

Our ultrasound technology was developed for application Our large custom-made equipment is at the forefront of technology thanks to more than 20 years of leadership in this field, with a market share over 80%.

Our equipment is especially recommended for the cleaning of large cylinder heads, injectors, pistons, exchangers, turbochargers and all types of mechanical elements. Marine Fuel Injector Cleaning

At UltraTecno we rely on specialized machinery to clean the engines of ships and other vessels,including marine fuel injector cleaning. For this reason, we use the best ultrasonic technology developed for its application in a multitude of industries, such as the automotive or marine industry, managing to achieve top results in all of them, and offering a planned maintenance system for ships. This is the result of years of work and research to offer our clients an effective solution to marine maintenance, compatible with every type of industrial processes. Marine ultrasonic cleaning machines using an ultrasonic cleaner are the best option for ship maintenance and for all sort of elements. Furthermore, large-scale machinery, manufactured with high-resistance materials is specially designed to support heavy loads. UltraTecno will not have any further problems with the ultrasonic cleaning of ship engines.

For over 50 years, UltraTecno specilizes in cleaning and maintenance of all kinds of injection molds.

Our solutions eliminate completely all remaining substances and materials, as zamak, aluminium, brass or any kind of burnt plastic or rubber.

Our solution provides excellent surface finishing ensuring complete absence of non-conformities due to quality in the production process. High cleaning standards after finishing a series provides faster response times to launch a new series after mounting the molds.

During the metal or plastic forming process the maintenance of the mold is a key factor together to the prime material for final product quality. As ultrasound cleaning specialists we designed and manufactured large amounts of ultrasonic cleaning machines for moulds industry during years.

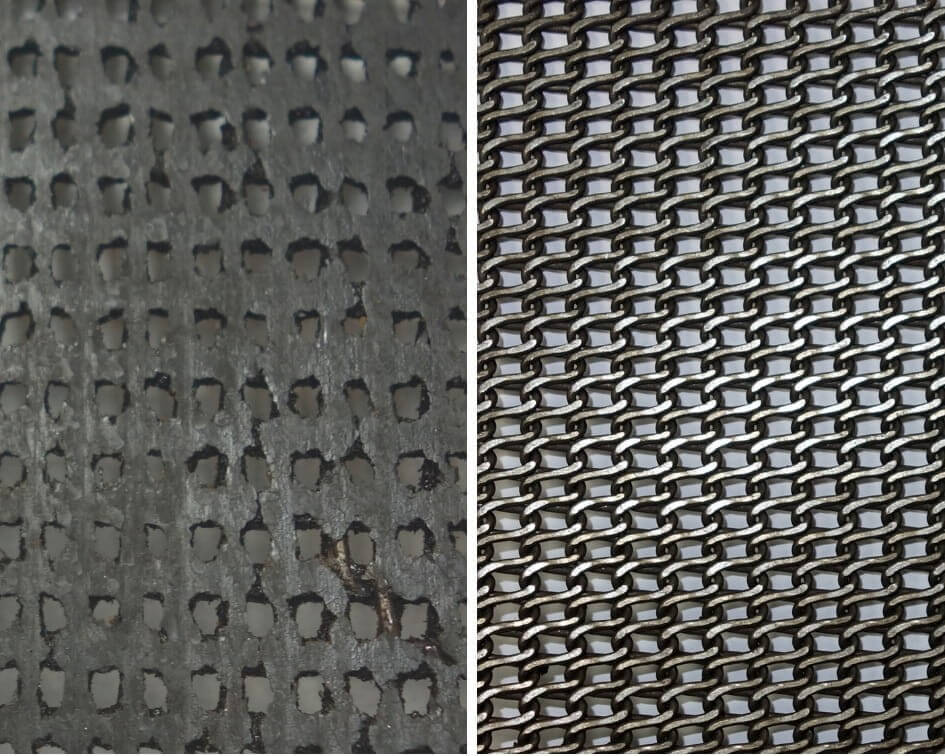

Reduce rejections due to quality control and obtain an excellent finish of your end products. We have achieved thehighest performance in ultrasound cleaning of moulds. Ultrasonic cleaning removes slightly the dirt accumulated on the mold surface (oils, dust, ink from plastic, rest of forming material and corrosion) without damaging the complex mold pattern.

UltraTecno will help you to improve your food production process saving time and money. Enforce the prerequisites, legal bases and critical control food points through the perfect cleaning of your pieces.

UltraTecno ultrasonic cleaning equipment not only removes rest of the food, burned dirt but also eliminates microbiological hazards achieving best hygiene and safety in the market.

Ultrasonic cleaning removes very quickly and effectively grease, oil, char, dust, sand, mud from the mining process. Our ultrasonic cleaning technology saves time and labor cost.

As peculiar your printing system may be, and regardless of the quality and printing inks used, UltraTecno provides a cleaning solution that minimizes your ink consumption and its internal rejections for quality. We specialize in the cleaning of anilox cylinders, and all types of printing tools and rollers, as our solution is focused on the specific softness required by each type of material.

UltraTecno have always placed wagers on the research of new applications focusing on ultrasound cleaning technology, gaining valuable experience throughout our professional career and exclusively devoting ourselves to provide perfect solutions to our clients. In this case, the cleaning process generated by our machinery known as cavitation, is the best option for the cleaning of printing and engraving rollers in every type of printing systems. The cleaning process releases the energy of millions of bubbles that implode by quickly eliminating all types of waste, and consuming few energy resources. As a result, our technology is one of the most efficient solutions to clean rollers or similar parts. Place your trust in UltraTecno and benefit from the multiple advantages of our machinery.

Its easy integration in every type of industrial processes guarantees the continuity of work at all times by optimizing its processes in many occasions, and improving the productivity of the cleaned parts. With UltraTecno technology you will enjoy of customized projects for all types of industries, such as the automotive or naval industry, optimizing multi-stage industrial processes or automated lines. Please contact us to inquire about the price of ultrasound equipment as our anilox cleaner. We guarantee you will receive the best advice by experienced professionals. Rely on UltraTecno to acquire the best anilox cleaning service of ultrasound equipment.

UltraTecno manufactures cleaning equipment specialized in cleaning of train engines and railways components.

Our ultrasound technology was developed for application in many industries such as the automotive or naval where is powerfull cavitation and big tanks are needed. Customers from railway industry cleani in ultrasonic tanks wide scope of train parts including – Gear box, Hot box or Axle box, stainless steal toilets or wagon interior parts.

Ultrasonic railway cleaning is postulated as the best option for train maintenance of all types of parts. Our ultrasonic cleaning equipment is specially designed to resist heavy loads, so you will not have problems cleaning railway engines anymore.

Ultratecno has always waged on constant innovation, creating and developing machinery to respond to the current and future needs of our clients.

The most prominent applications of this technology include cleaning machines through ultrasonic cavitation equipment, cavitation and ultrasounds cleaning The technology offers multiple benefits to its users. Ultrasonic cavitation machines guarantee an excellent cleaning process for every type of parts with the maximum level of energy efficiency.

The High Power Ultrasounds have become a feasible alternative to many conventional processes in the industry.

Ultrasonic cleaning removes very quickly and effectively greases, oil coolant, dirt from metal parts and plastic, chips, polishing pastes and more dirt from the manufacturing process. Our ultrasonic cleaning technology saves time and labor cost.

Our technology arrives where traditional methods can not, adding value and quality to your manufacturing process.

Ultratecno offers the best washing and degreasing system for the treatment of surfaces, improving it is process and final product quality. Save money and time eliminating grease, dirt, plastics, metals and polishing pastes.